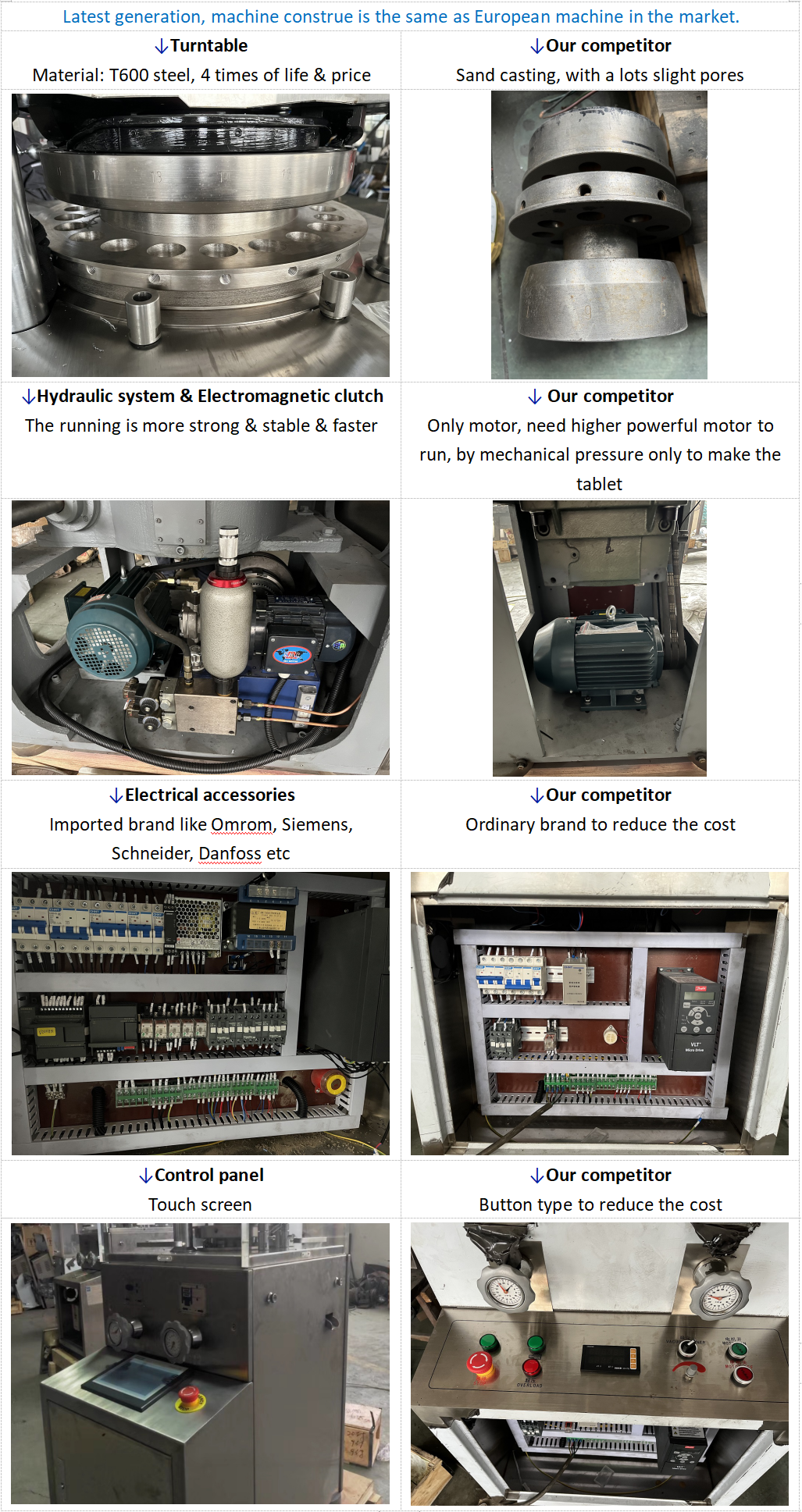

Automatic Rotary Salt Tablet Press Machine

ZP29F Tablet press machine

Sample

Use

This equipment is an electromechanical high-tech product developed on the basis of years of automated product inspection developed by our company. It can suppress various conventional wafers and other special-shaped tablets (including double-sided printing): This equipment is pharmaceutical, chemical, The best choice for food, plastic, electronics and other production enterprises.

This equipment is an electromechanical high-tech product developed on the basis of years of automated product inspection developed by our company. It can suppress various conventional wafers and other special-shaped tablets (including double-sided printing): This equipment is pharmaceutical, chemical, The best choice for food, plastic, electronics and other production enterprises.

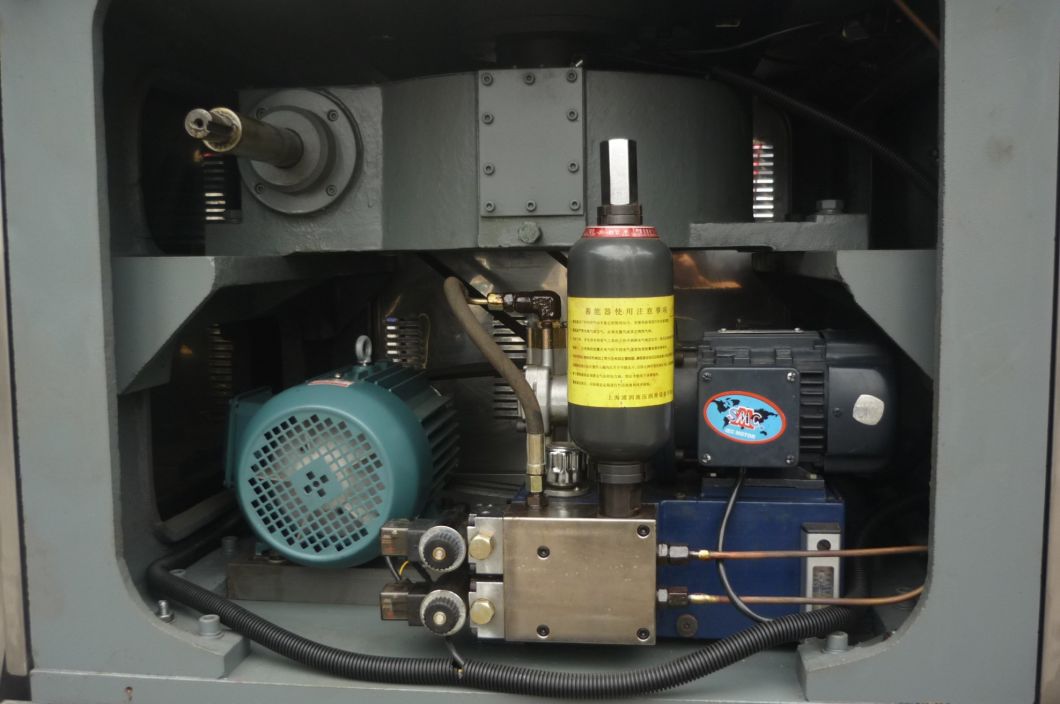

Features

1.The overall structure of the equipment is compact and reasonable. It has the advantages of beautiful appearance, high production efficiency, low energy consumption, and easy operation.

2. The frame adopts stainless steel anti-corrosion, and the surface is specially polished to prevent cross-infection and meet the GMP standard.

3.It is equipped with a transparent plexiglass window, which can observe the running process of the tablet at any time. The window can be opened for cleaning and maintenance.

Parameter

| ZP23F | ZP25F | ZP27F | ZP29F | ZP31F | |

| Press die qty. | 23 stations | 25 stations | 27 stations | 29 stations | 31 stations |

| Max. filling depth (mm) |

17mm | 17mm | 17mm | 17mm | 17mm |

| Max. tablet press dia. (mm) |

27mm (Irregular 16mm) |

25mm (Irregular 16mm) |

25mm (Irregular 16mm) |

20mm | 20mm |

| Max. tablet thickness (mm) |

7mm | 8mm | 8mm | 7mm | 7mm |

| RPM | 14-30 r/min | 14-30 r/min | 14-30 r/min | 16-36 r/min | 16-36 r/min |

| Production capacity (Tablet/hr) |

40000-83000 | 40000-90000 | 40000-95000 | 125000 | 134000 |

| Power supply | 3kw 380V 50Hz 220V 60Hz |

3kw 380V 50Hz 220V 60Hz |

3kw 380V 50Hz 220V 60Hz |

3kw 380V 50Hz 220V 60Hz |

3kw 380V 50Hz 220V 60Hz |

| Overall dimension (mm) (LxWxH) |

1300*1200 *1750 |

1300*1200 *1750 |

1300*1200 *1750 |

1300*1200 *1750 |

1300*1200 *1750 |

| Net weight (Kg) |

2000 | 2000 | 2000 | 2000 | 2000 |

RFQ

Write your message here and send it to us