China Manufacturer for Automatic Bread Packing Machine - Njp Series Pharmaceutical Equipment/Machinery Automatic Coffee Capsule Filling Machine, Automatic Capsule Filler, Capsule Making Machine – Yidao

China Manufacturer for Automatic Bread Packing Machine - Njp Series Pharmaceutical Equipment/Machinery Automatic Coffee Capsule Filling Machine, Automatic Capsule Filler, Capsule Making Machine – Yidao Detail:

Product advantages:

1. Independently develop and improve the internal design of the die turntable, and use original Japanese linear bearings, which have higher accuracy and longer service life than counterpart equipment.

2. The design of the lower cam, compared with its counterparts, we have increased the pressure atomizing oil pump to maintain the lubrication in the cam groove, which greatly reduces wear and prolongs the service life of parts.

3. The upper and lower modules are designed for one-way movement, and the imported double-lip polyurethane sealing ring has better sealing performance.

4. The control panel is eye-catching and intuitive, and adopts stepless variable frequency speed regulation.

5. The three-dimensional adjustment mechanism based on the lower plane of the measuring plate is used to make the gap more uniform and the loading difference more accurate.

6. Equipped with safety protection devices for people and machines, with automatic shutdown device for lack of materials, to achieve more stable machine operation, safety and reliability.

7. The combination of air blowing and gas suction of the module has been added to ensure that the mold holes are clean and free of dust and improve the probability of operation.

8. Independent design of 2 sprockets drives 2 indexing boxes to separate labor. (Peer is generally a sprocket to drive 2 indexing boxes.) Reduces resistance, shares operating pressure, increases operating intensity, and the station’s fault is basically zero.

Machine specification and parameter:

| Model | NJP-1200 | NJP-2500 | NJP-3500 | NJP-3800 | NJP-7500 |

| Output (PCS/H) | 12000 | 24000 | 36000 | 48000 | 60000 |

| Capsule sizes | 00#~4# & safety capsule A~E | 00#~4# & safety capsule A~E | 00#~5# & safety capsule A~E | 00#~5# & safety capsule A~E | 00#~5# & safety capsule A~E |

| Total power | 3.32kw | 3.32kw | 4.9kw | 4.9kw | 5.75kw |

| Net weight | 700kg | 700kg | 800kg | 800kg | 900kg |

| Dimension (mm) | 720×680×1700 | 720×680×1700 | 930×790×1930 | 930×790×1930 | 1020×860×1970 |

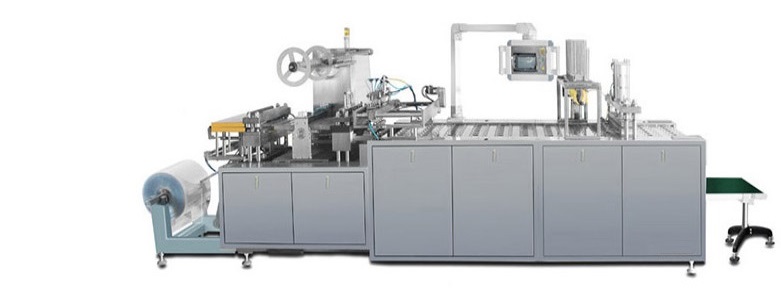

Machine details:

Factory tour:

Expot Packaging:

RFQ:

1. Quality warranty

One year warranty, free replacement due to quality problems, non-artificial reasons.

2. After-sales service

If need seller to provide service at customer’s plant. buyer need to bear visa charge, air ticket for round trips, accommodition, and daily salary.

3. Lead time

Basically 25-30 days

4. Payment terms

30% advance, the balance need to be arranged before the delivery.

The customer need to check the machine before delivery.

Product detail pictures:

Related Product Guide:

Sticking for the perception of Creating products of top quality and producing friends with people today from all around the world, we constantly place the desire of shoppers to start with for China Manufacturer for Automatic Bread Packing Machine - Njp Series Pharmaceutical Equipment/Machinery Automatic Coffee Capsule Filling Machine, Automatic Capsule Filler, Capsule Making Machine – Yidao , The product will supply to all over the world, such as: Tunisia, Toronto, Bangladesh, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve goods and give more detailed services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.