China New Product Peanut filling packing machine - Automatic Surgical Nonwoven Disposable Face Mask Making Machine – Yidao

China New Product Peanut filling packing machine - Automatic Surgical Nonwoven Disposable Face Mask Making Machine – Yidao Detail:

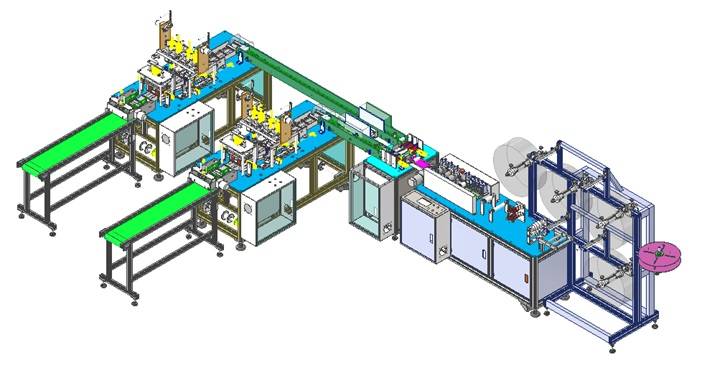

Automatic disposable mask making machine

This machine is mainly used for automatic forming of plane mask: the whole roll of cloth is driven by roller after being unrolled, and the cloth is folded and wrapped automatically.The nose bridge strip is rolled up for traction and unrolled. After cutting with a fixed length, it is imported into the edge cloth. The two sides are welded to the seal by ultrasonic welding.The mask was transported to two mask ear belt welding stations by the assembly line, and the mask was finally formed by ultrasonic welding.After the mask is made, it is transported to the flat belt line through the assembly line for collection.

This machine is mainly used for automatic forming of plane mask: the whole roll of cloth is driven by roller after being unrolled, and the cloth is folded and wrapped automatically.The nose bridge strip is rolled up for traction and unrolled. After cutting with a fixed length, it is imported into the edge cloth. The two sides are welded to the seal by ultrasonic welding.The mask was transported to two mask ear belt welding stations by the assembly line, and the mask was finally formed by ultrasonic welding.After the mask is made, it is transported to the flat belt line through the assembly line for collection.

Equipment installation and environmental requirements

Equipment size::6850mm(L)×3600mm(W)×1900mm(H);

Appearance color: RAL9003,Follow this standard unless otherwise specified

Equipment weight: ≤5000kg, ground load ≤500KG/m2;

POWER:220VAC±5,50HZ,

Rated power: 9KW;

Equipment weight: ≤5000kg, ground load ≤500KG/m2;

Compressed air: 0.5-0.7mpa, compressed air flow: about 300L/min;

Operating environment: temperature 10 ~ 35ºC, humidity 5-35%HR, no combustible, corrosive gas, no dust (cleanliness not less than 100,000).

Production speed: approximate 80-120 Nos. Per Min.

Main components brand configuration

| NO. | Item | Brand | Remark |

| 1 | Cylinder | CKD,SMC/Japan, AirTAC, MISUMI/Taiwan | |

| 2 | Solenoid valve | CKD,SMC,Japan, AirTAC | |

| 3 | Servo motor | Mitsubishi/Japan, Panasonic/Japan | |

| 4 | PLC | Huichuan/China, Mitsubishi, Omron/Japan | |

| 5 | Ordinary governor motor | Jingyan/China | |

| 6 | Bearing | NSK/ Japan, HRB/ China | |

| 7 | Guide Rail | STAF, PMI, CPC, HIWIN/ Taiwan | |

| 8 | Optical fiber amplifier | Omron,Keyence, Panasonic/Japan | |

| 9 | Touch screen | Weinview/Kunluntongtai | |

| 10 | Relay | Omron/IDEC | |

| 11 | Button | SHUANGKE |

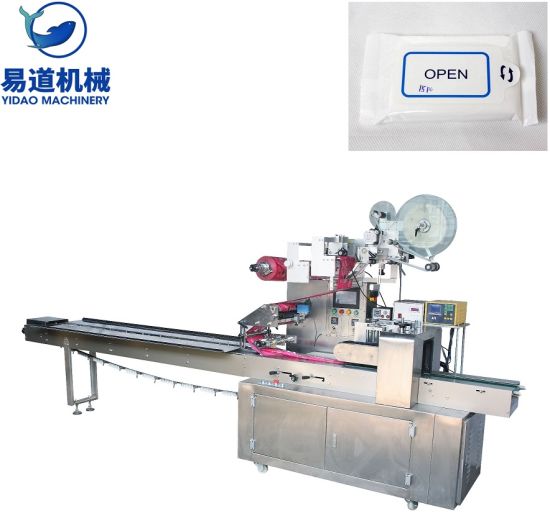

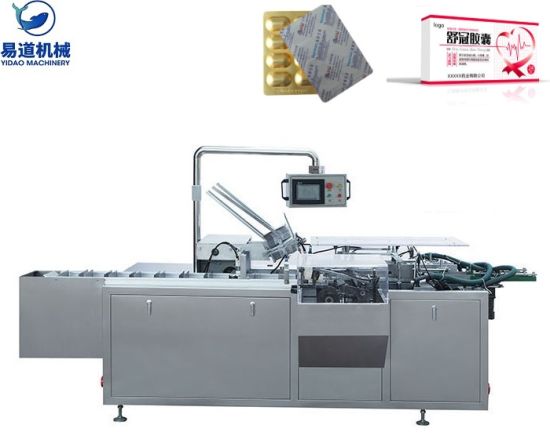

Sample photos

Factory photos

Product detail pictures:

Related Product Guide:

We stay with the basic principle of quality initially, services first, steady improvement and innovation to fulfill the customers for your management and zero defect, zero complaints as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for China New Product Peanut filling packing machine - Automatic Surgical Nonwoven Disposable Face Mask Making Machine – Yidao , The product will supply to all over the world, such as: Casablanca, Singapore, Mombasa, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.