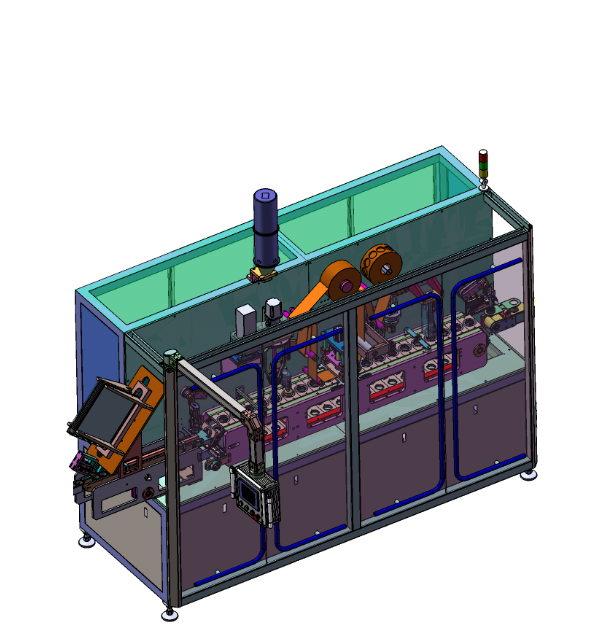

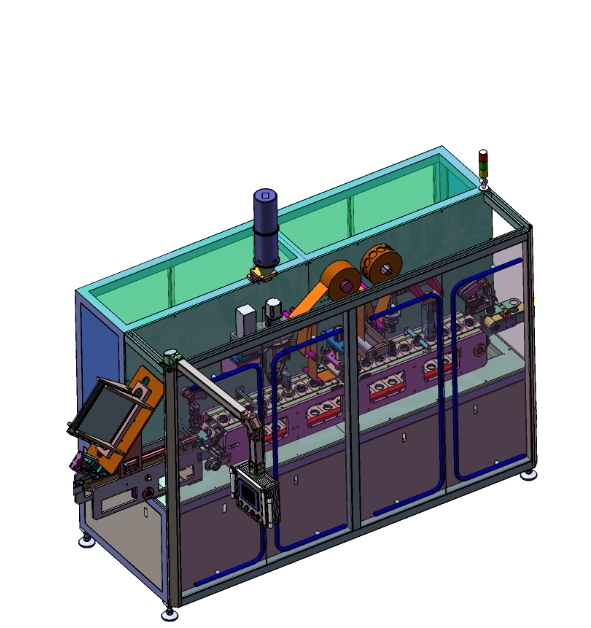

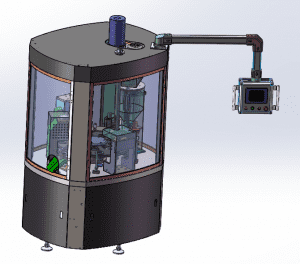

Coffee capsule dolce gusto nespresso cartoning machine boxing machine

NO 1. Machine Introduction

The machine is our rolled film + sheet film linear model, fast and stable, it can fill 3000-3600 capsules per hour, it can fill a variety of cup types, servo-controlled spiral canning, canning accuracy can reach ± 0.3 g. With nitrogen filling function, so that the residual oxygen of the product can reach 5%, can extend the shelf life of coffee. The whole machine system is based on Schneider and developed with IoT technology, with the option of computer/cell phone, to monitor or operate the machine online.

NO 2. Scope of application

The machine is suitable for weighing and canning of various granular, powder and liquid materials. Such as coffee powder, milk powder, soya milk powder, tea, instant powder, yoghurt and other food materials.

NO 3. Main functions and features of the filling machine

1. Fully automatic completion of the packaging process, small footprint of the machine, simple and easy to operate.

2、PLC control system, full display and real time monitoring, and can be operated online by computer/mobile phone “optional”.

3、Automatic cup dropping, large cup storage bin, reducing the number of manual cup filling, greatly saving labour costs.

4、Automatic canning, leak-proof servo screw, high precision canning, stable test up to plus or minus 0.3g.

5、Automatic cup edge dust removal, using rotary suction and pressure test dust removal, the solidity and beauty of the cup edge sealing is greatly improved.

6、Automatic film suction and release.

7、Nitrogen flushing system, nitrogen protection throughout the whole process from cup dropping to sealing, the residual oxygen content of the product can reach 5%.

8、Automatic sealing, the sealing and firmness of the seal is more perfect.

9、Automatic cup dispensing.

10、Automatic record of the number of packaged products.

11、Failure alarm stopping function.

12、Safety is greatly improved.

NO 3. Technical parameters of the filling machine

| Model: | RN2C-40 |

| Food material: | Ground/coffee, tea, milk powder |

| Maximum speed: | 3600 grains/hour |

| Voltage: | 3 phase 220V three-phase 380V “can be customized according to customer voltage |

| Power: | 7.0KW |

| Frequency: | 50/60HZ |

| Air pressure supply: | ≥0.6Mpa / 0.1㎥ 0.8Mpa |

| Equipment weight: | 1800kg |

| Equipment size: | Filling machine length 3800mm×width 1000mm×height 1900mm |

| Oversize | Length 1500mm×width 500mm×height 700mm |

NO 4. Electrical configuration

| PLC system: | Schneider |

| Touch screen: | flexem |

| Inverter: | Schneider |

| Servo motor: | Schneider |

| Circuit breaker: | Schneider |

| Button switch: | Schneider |

| Encoder: | OMRON |

| Temperature control meter: | OMRON |

| Light large sensor: | Panasonic |

| Small relay: | Wazumi |

| Solenoid valve: | Airtac |

| Vacuum valve: | ADATA |

| Pneumatic components: | Airtac |