DSL-8B Electronic capsule tablet counting & filling machine

Video 1, https://youtu.be/TQe7D3zWmxw

Automatic Bottle Unscrambler – > Automatic capsule tablet counting & filling machine -> Automatic Capping machine -> Automatic sealing machine -> Automatic labeling machine -> Automatic storage machine

https://youtu.be/GcIp_LJhGSA

Semi automatic bottle Unscrambler – > Automatic capsule tablet counting & filling machine -> Automatic Capping machine -> Automatic sealing machine

DSL-8B Electronic counting machine

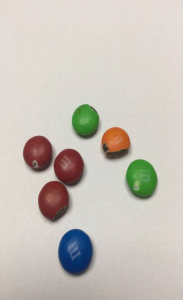

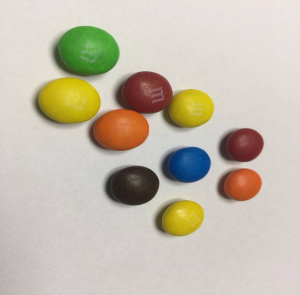

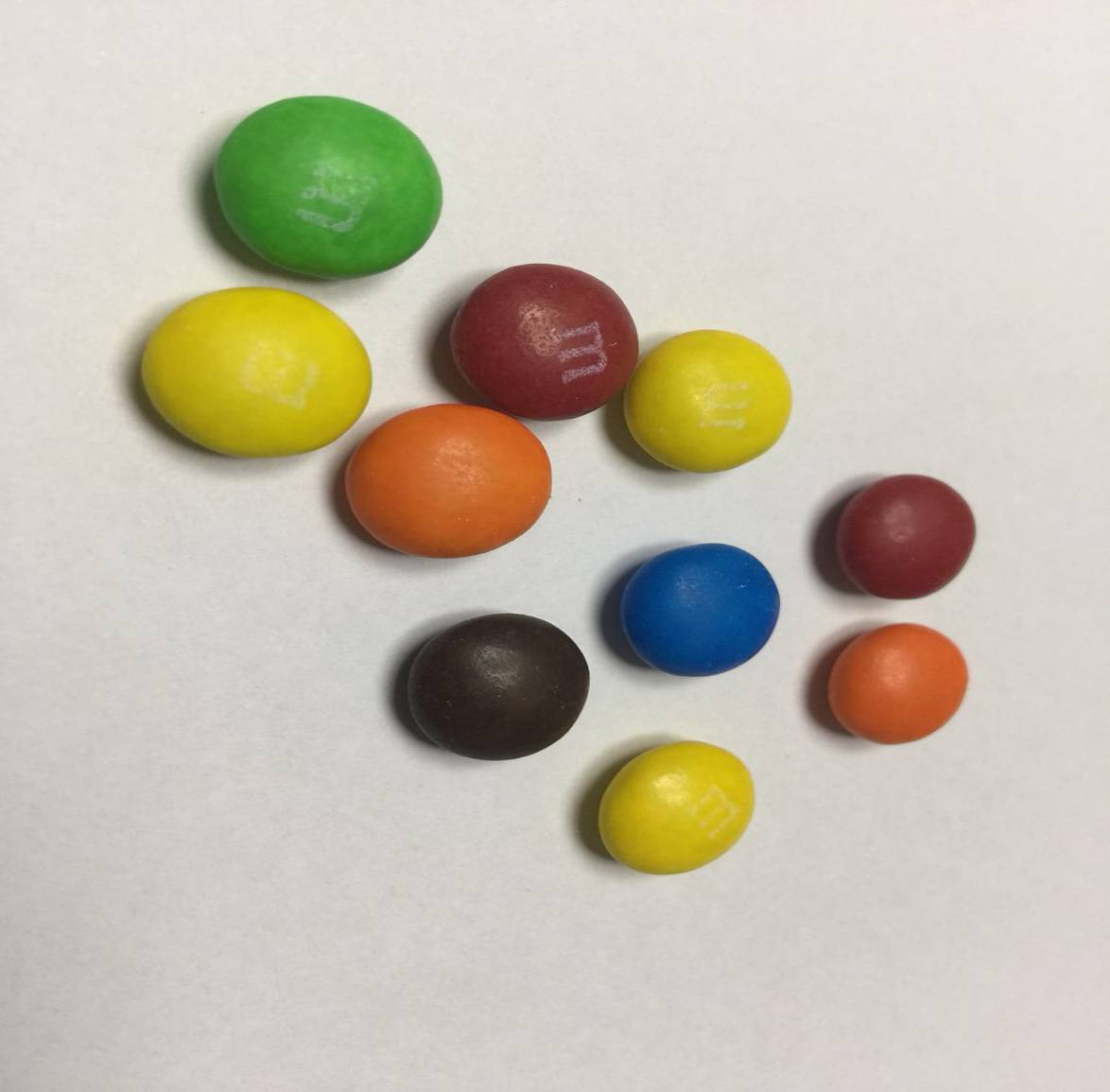

This model is the fourth generation innovative product of our company. It can pack all kinds of tablets and capsules (transparent or opaque hard capsules, soft capsules, pills, etc.) in the range of 3-25 mm.Meet the requirements of GMP, suitable for scientific research institutions, hospitals, small and medium-sized pharmaceutical factories, health products factory production packaging

1、High accuracy.The accuracy rate of several canned grains is more than 99.5, which is higher than the industry standard.

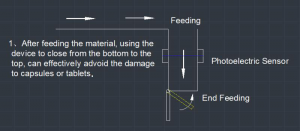

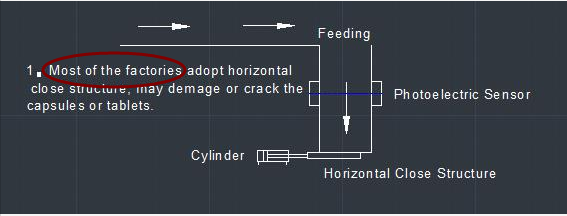

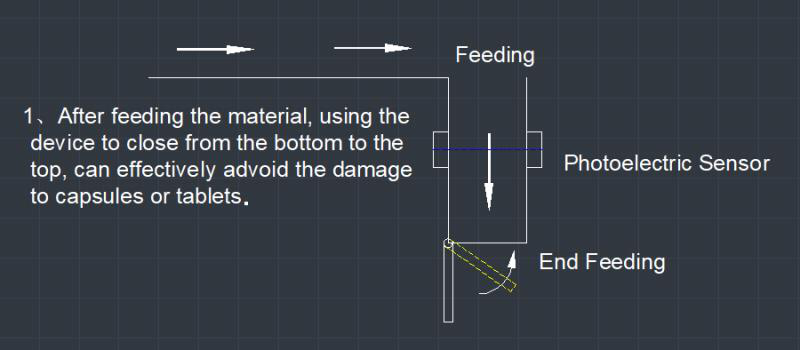

2、The flip-flop subassembly mechanism obtains the national patent, does not damage the material when opening and closing.

3、Good stability.Using the electronic counting technology of high dust resistance, it can still operate normally in high dust environment.

4、Strong compatibility, wide scope of application.All kinds of tablets, capsules (transparent or opaque hard capsules, soft capsules, pills, etc.) can be counted and canned.

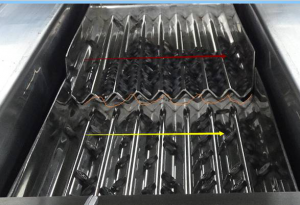

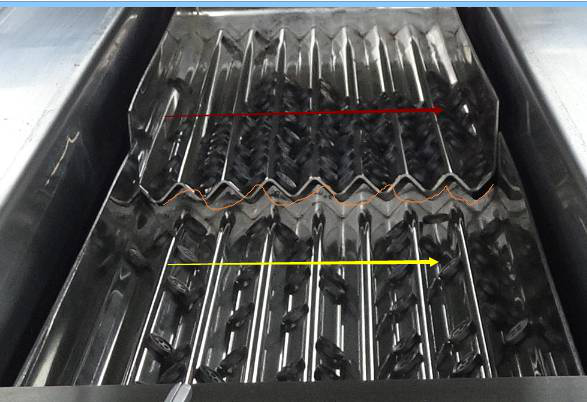

5、Multistage vibration design.Large size, irregular, high viscosity materials can be effectively separated, accurate count.

6、 High intelligence.With the bottle, materials, all kinds of online fault monitoring function, and automatic alarm.

7、 High integration.Can be based on the size of the customer site, output, front and back of the process line control, improve efficiency, save labor.

8、easy to use.Small area, easy to remove and clear without any tools.

9、low running cost .High cost-performance products, low cost of use and maintenance, the original machine configuration for one year of easy-to-wear parts.

10、For easy clogging and special feeding varieties can be customized according to actual needs.(optional)

11、the quality is reliable.The machine adopts stainless steel 304, material contact part uses stainless steel 316 material.

12、equipped with dust collection box, centralized dust collection, reduce pollution.

| Production capacity | 10~30 bottles/min |

| accuracy rate | >99.5% |

| Applicable target | #00-5 capsule, soft capsule, Ø 5.5-25 tablet,shaped,sugarcoated tablet and Ø3-20 pill |

| Filling range | 2-9999 grains (tablets) adjustable |

| Applicable bottle type | 10-500ml round, square bottle |

| voltage | 380/220V 50Hz |

| power | 0.6KW |

| pressure | 0.6Mpa |

| weight | 360kg |

| Outline dim.(mm) | 1400×1650×1650mm |

|

Number |

item |

Qty. | Manufacturer |

|

1 |

Motor | 1 | Taiwan TQG |

|

2 |

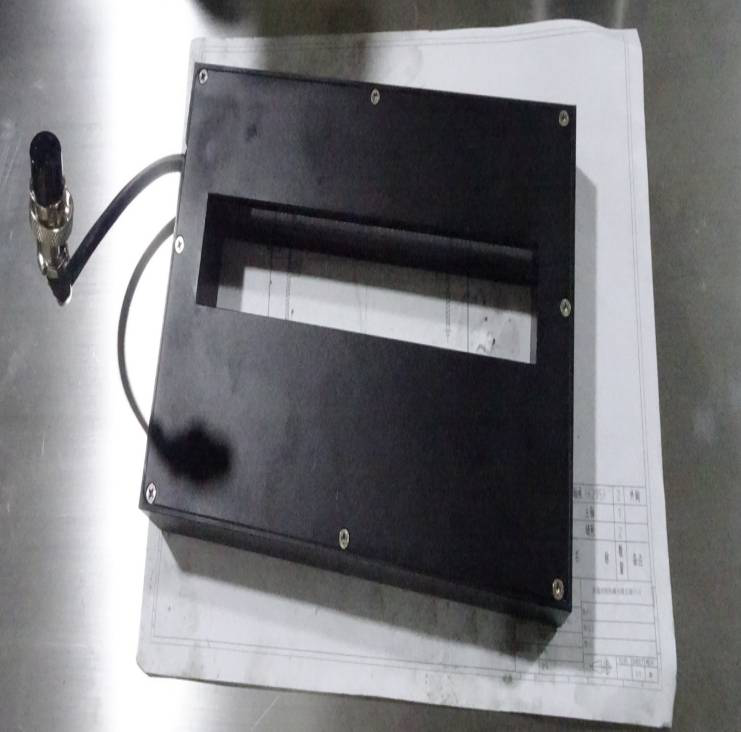

Counting photoelectric head | 1 | Taiwan |

|

3 |

Bottle photoelectric eye | 1 | Panasonic |

|

4 |

Button | 1 | Schneider |

|

5 |

Touch screen | 1 | Siemens |

|

6 |

CPU | 1 | ST |

|

7 |

Power | 1 | Schneider |

|

8 |

Pneumatic elements | 1 | Shanghai |

|

9 |

earth leakage protection | 1 | Schneider |

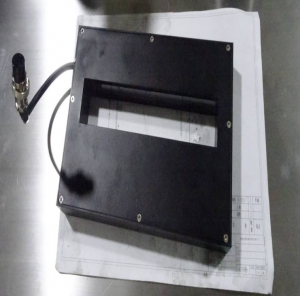

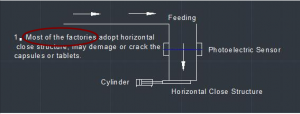

1.High-power photoelectric detection

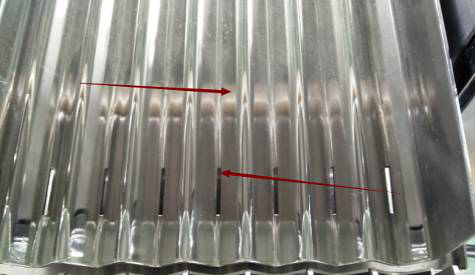

2.Multistage vibration cutting

3.Flip plate structure

Ours

4.The contact part with the material is made of stainless steel 316

5.Hopper observation window,can check the quantity of materials at any time and add materials in time.

6.Siemens touch screen and emergency button,emergency stop when machine fails.

7.Fault warning light,when the machine fails, the warning lights promptly remind, convenient maintenance and save time.

8.Tempered glass window, you can check the machine’s blanking process, if there is a fault, you can adjust it in time.

9.Bottle photoelectric eye

10.Electrical system

11.Dust storage box