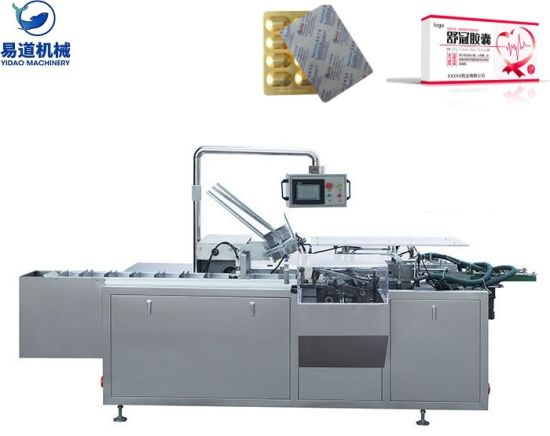

Factory For Plaster packing machine - Flow Packing Machine for Biscuits /Cookie / Chocolate Bar/ Mochi / Pineapple Cake – Yidao

Factory For Plaster packing machine - Flow Packing Machine for Biscuits /Cookie / Chocolate Bar/ Mochi / Pineapple Cake – Yidao Detail:

2. Scope of application:

2. Scope of application:

Apply more material blocks(such as betel,olives,candied fruit,gong date),multiple packet soup,solid dispersing materials,small electronic components of irregular objects.

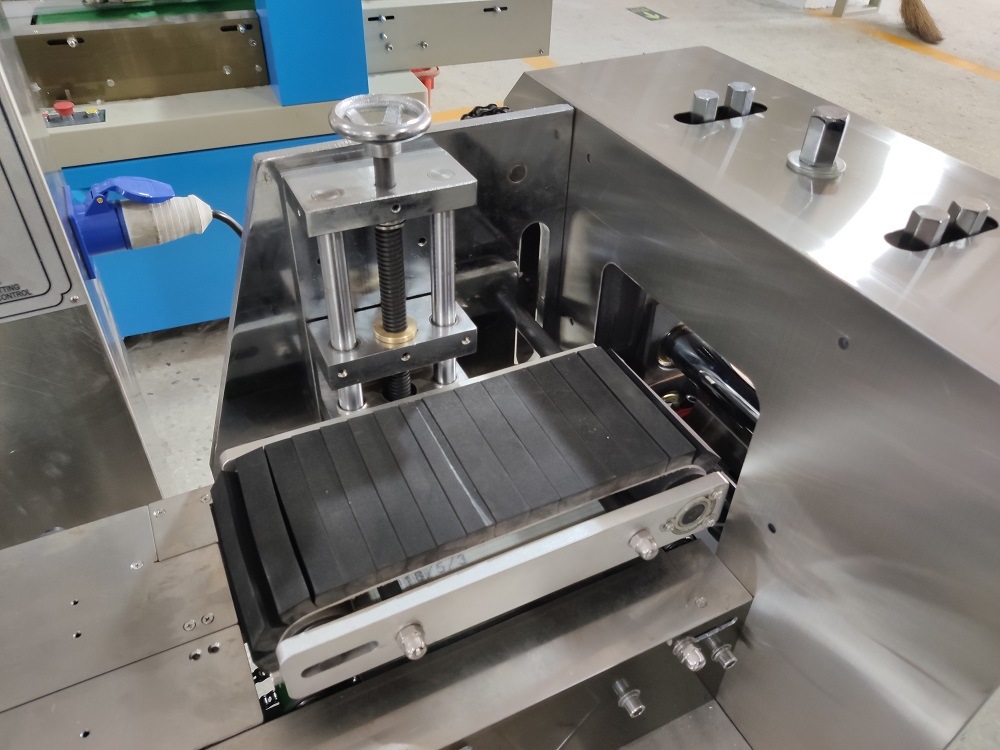

Compact structure, stable function and simple operation.

Double frequency converter controller,length of package will cut immediately once setting, adjustment needless, saving time and film.

It adopts imported electric appliance, touch manmachine interface, convenient parameter setting.

Self-cheching function, trouble can be read easily. High sensor photoelectric color chart tracking, make the cutting position more correctly.

Dependant temperature PID controlling suitable for various materials of packagingmenbrane.Position stop function, no adhesive and no waste of membrane.

Clean rotation system, more reliableoperation and more convenient maintenance.

All the controlling operates by the software,convenience for function ad-justment and technical up grading.

| Model | KD-350 | KD-350A | KD-350B |

| Max film width | 340mm | 350mm | 350mm |

| Max packaging capacity (according to its material to confirm) |

40-200 times/min | 40-220 bags/min | 50-150 times/min |

| Suitable film thickness | 0.03-0.06mm | 0.03-0.06mm | 0.03-0.06mm |

| Length of bags | 65-330mm | 60-220mm | 65-330mm |

| Packaging width | 30-160mm | 25-100mm | 30-150mm |

| Packaging height | ≤55mm | ≤55mm | ≤50mm |

| Total power | 3.2Kw 220V | 2.4Kw 220V | 3.2Kw 220V |

| Overall dimensions(L x W x H) | 4100 x 1050x1560mm | 4000 x 920x1500mm | 4100 x 1050x1560mm |

| Weight | 600KG | 600KG | 680KG |

| Type | Horizental | Reverse | Lower feeding |

| Application | Suitable for biscuits, packaging of all kinds of objects with regular solid state, such as bread, speed wheaten food, moon cake, candy, medicines, daily necessities, hardware, paper carton or the tray, etc. | Apply for material blocks such as betel, olives, candied fruit, gong date, multiple packet soup, solid dispersing materials, small electronic components of irregular objects. | Suitable for soft strip packaging, such as towel, paper towel, dried noodles, omelet, banger, sleeve-fish, ice-lolly, candy. |

1.Compact structure, stable performance, easy maintenance. The double frequency conversion control, bag length is set is cut, don’t need to adjust empty, one pace reachs the designated position, time-saving membrane uses the Sifang imported frequency converter

2.Touch human-machine interface, convenient and quick parameter setting fault self-diagnosis function, fault shows at a glance.Look the Gao Gan degree of photoelectric tracking,

3.Temperature independent PID control, better suited to a variety of material coated.Positioning stop function, non-stick knives, at no cost

Adopt import stepper motor. The noise is small, the tracking accuracy!Optional (servo motor)

5. All control by the software implementation, convenient function adjustment and technology upgrade, never backward.6. The rotation system is concise, more reliable, more convenient maintenance.

Adopt import stepper motor. The noise is small, the tracking accuracy!Optional (servo motor)

6. All control by the software implementation, convenient function adjustment and technology upgrade, never backward.

6. Factory tour:

7. RFQ:

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for Factory For Plaster packing machine - Flow Packing Machine for Biscuits /Cookie / Chocolate Bar/ Mochi / Pineapple Cake – Yidao , The product will supply to all over the world, such as: Mongolia, Ukraine, Mauritania, You can always find the products you need in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We are looking forward to work with you for a win-win situation.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.