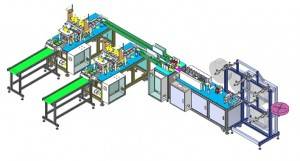

KN95 N95 Fully Automatic Face Mask Making Machine

Fully automatic KN95 mask production line

Machine Profile.

The production line is fully automated for KN95 masks. Mainly includes coil loading, nose strip loading, mask embossing, earbands and welding, mask folding, mask sealing, mask cutting and other processes. The entire production process, from raw materials to finished masks, is completed. The masks produced are comfortable to wear, non-pressurizing, efficient in filtration, and suitable for face shape.

Machine characteristics.

1. The frame is made of aluminum alloy and cold-rolled plate paint, which is light and beautiful in appearance and does not rust.

2. automatic counting, can adjust the equipment running speed according to the actual need, can effectively control the production efficiency and production progress.

3. The pulling barrel feeds the material, the positioning is more accurate, the width of the raw material can be controlled to a minimum, saving costs.

4. Uniform dimensional control of finished product length, deviation ± 1mm, can effectively control the finished product length.

5. A high degree of automation and low requirements for operating staff, requiring only the discharge and finishing of finished products.

Machine configuration.

1. Ultrasonic system, transducer, stable performance and easy operation.

2. Automatic ultrasonic welding wheel, made of high quality steel DC53, makes the mold life longer, wear-resistant and durable.

3. Computer PLC programming control, high stability, low failure rate, low noise.

4. Servo motor and stepper motor drive for high precision.

5. Photoelectric testing materials to avoid errors and reduce waste.

Machine parameters.

| Dimension(L*W*H) | 900*160*200 cm |

| Weight | 3000 KG |

| Voltage | 220V/50Hz |

| Pressure | 0.4-0.6 Mpa |

| Frame material | Aluminum alloy |

| Control Mode | PLC |

| Warranty | 1 YEAR |

| Certification | |

| Capacity | 40 pcs/min |

| Raw material specification | Non-woven fabric,Width 260 mm Hot air cotton,Width 260 mm Melt thrown,Width 260 mm skin-friendly nonwoven fabric,Width 260 mm |