OEM manufacturer Capsule Filling Machine Size 000 - Dpp-80 Automatic Pharmaceutical Equipment Capsule/Liquid/ Choclate Blister Packing Packaging/Package/Pack Machine – Yidao

OEM manufacturer Capsule Filling Machine Size 000 - Dpp-80 Automatic Pharmaceutical Equipment Capsule/Liquid/ Choclate Blister Packing Packaging/Package/Pack Machine – Yidao Detail:

2. Features:

1. It adopts the newest type high-power transmission mechanism to arrange the chain and drive the main driving shaft. The errors and noises of other gear wheel transmission can be avoided.

2. Imported controlling system is adopted; also it can be equipped with detecting and rejection function device (Omron Sensor) Dpp-80 Manufacturing Pharmaceutical Packing Packaging/Package Pack Machine, Blister Packing Machine for number of medicines according to the user’s requirement.

3. It adopts photoelectrical controlling system to make PVC, PTP, Aluminum/Aluminum material to be automatically fed and waste side to be cut automatically to guarantee the Synchronous stability of over- length distance and multi stations.

4. It can be optional equipped with photocell correction device, imported stepper motor traction and image- character register to optimize packing grade.

5. The machine is suitable for industries of foodstuff, medicine, medical instruments, hardware, electronics and etc for packing.

3. Technical specifications:

| Model | DPP-80 | DPP-120 | DPP-150 |

| Punch frequency | 10-33times/min | 10-33times/min | 10-35times/min |

| Production capacity | 1980plates/hour | 2400plates/hour | 1200-4200plates/hour( two plates one time) |

| Max. Forming area & Depth | 105×70(standard depth <=15mm), Max. Depth 25mm( As adjusted | 125×75(standard depth <=15mm), Max. Depth 25mm( As adjusted | 130×100(standard thickness≤15mm) Max. depth 26mm |

| Standard Stroke range | 30-80mm(can be designed as per user’s required) | 30-80mm(can be designed as per user’s required) | 50-120mm(can be designed as per user’s required) |

| Standard plate size | 80x57mm (can be designed as per user’s required) | 80x57mm (can be designed as per user’s required) | 80x57mm (can be designed as per user’s required) |

| Air pressure | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Compressed air required | Air compressor≥0.3m3/min | Air compressor≥0.3m3/min | Air compressor≥0.3m3/min |

| Total power supply | 220V 50Hz 2.4Kw | 220V 50Hz 1 phase 2.8Kw | 380V 50Hz 3.8Kw |

| Main motor | 0.75Kw | 0.75Kw | 1.5Kw |

| PVC hard Film | 0.15-0.5*110 (mm) | 0.15-0.5*125 (mm) | 0.15-0.5*150 (mm) |

| PTP Aluminum film | 0.02-0.035*110 (mm) | 0.02-0.035*125 (mm) | 0.02-0.035*150 (mm) |

| Cold stamped aluminum | 0.14-0.16 110(mm) | ||

| Dialysis Paper | 50-100g*110(mm) | 50-100g*15(mm) | (0.02∽0.035)×150mm |

| Mould cooling | Tap water or Recycling water | Tap water or Recycling water | Tap water or Recycling water |

| Overall Dimension | 1840x590x1100 (mm)(LxWxH) | 1840x590x1100 (mm)(LxWxH) | 2315×635×1405mm(L×W×H) |

| Weight | Net 425kg Gross weight: 475kg | Net 415kg Gross weight: 465kg | Net 820kg Gross weight: 890kg |

| Noise index | <75dBA | <75dBA | <75dBA |

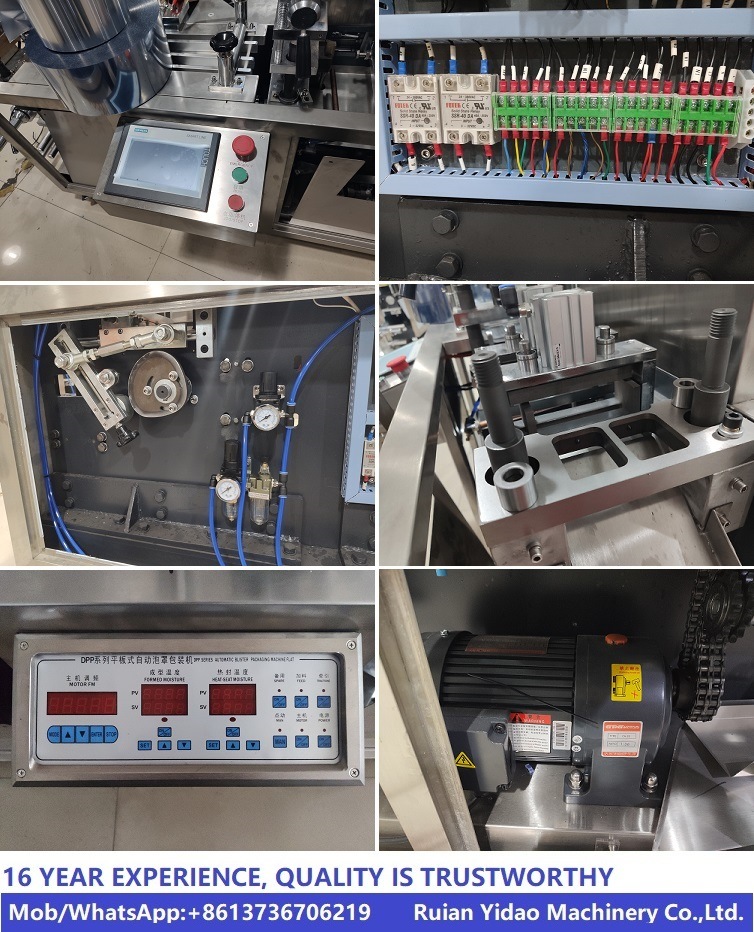

4. Machine details:

Option

1. PLC + Touch

2. Indentation device

3. Ornaic glass cover

4. cursor positioning

5. Machinery forming

6. Recovery device

5. Samples:

6. Factory tour:

7. Packaging:

8. FAQ

1. How do we know the model is suitable for our target capacity?

A: Pls tell us how many blisters do you want to pack in one hour, what are you going to pack, what is the size of blister sheet, then we will design and choose the most cost-effective blister packaging machine for you.

2. Can I pack two kinds or more of different sizes of blisters by one machine?

A: Yes, pls tell us your requests of the size you are going to pack, we will design different mould for you to change.

3. What kind of products can you pack with this machine?

A: we can pack different products, like capsules, tablets, vials, ampoules, candies, electronic products, liquids, and many other products.

Product detail pictures:

Related Product Guide:

Our goal is to satisfy our customers by offering golden service, good price and high quality for OEM manufacturer Capsule Filling Machine Size 000 - Dpp-80 Automatic Pharmaceutical Equipment Capsule/Liquid/ Choclate Blister Packing Packaging/Package/Pack Machine – Yidao , The product will supply to all over the world, such as: Ukraine, Albania, Guatemala, To keep the leading position in our industry, we never stop challenging the limitation in all aspects to create the ideal products. In his way, We can enrich our life style and promote a better living environment for the global community.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.