OEM Manufacturer Pill Making Machine - Box Packing Machine for Biscuit – Yidao

OEM Manufacturer Pill Making Machine - Box Packing Machine for Biscuit – Yidao Detail:

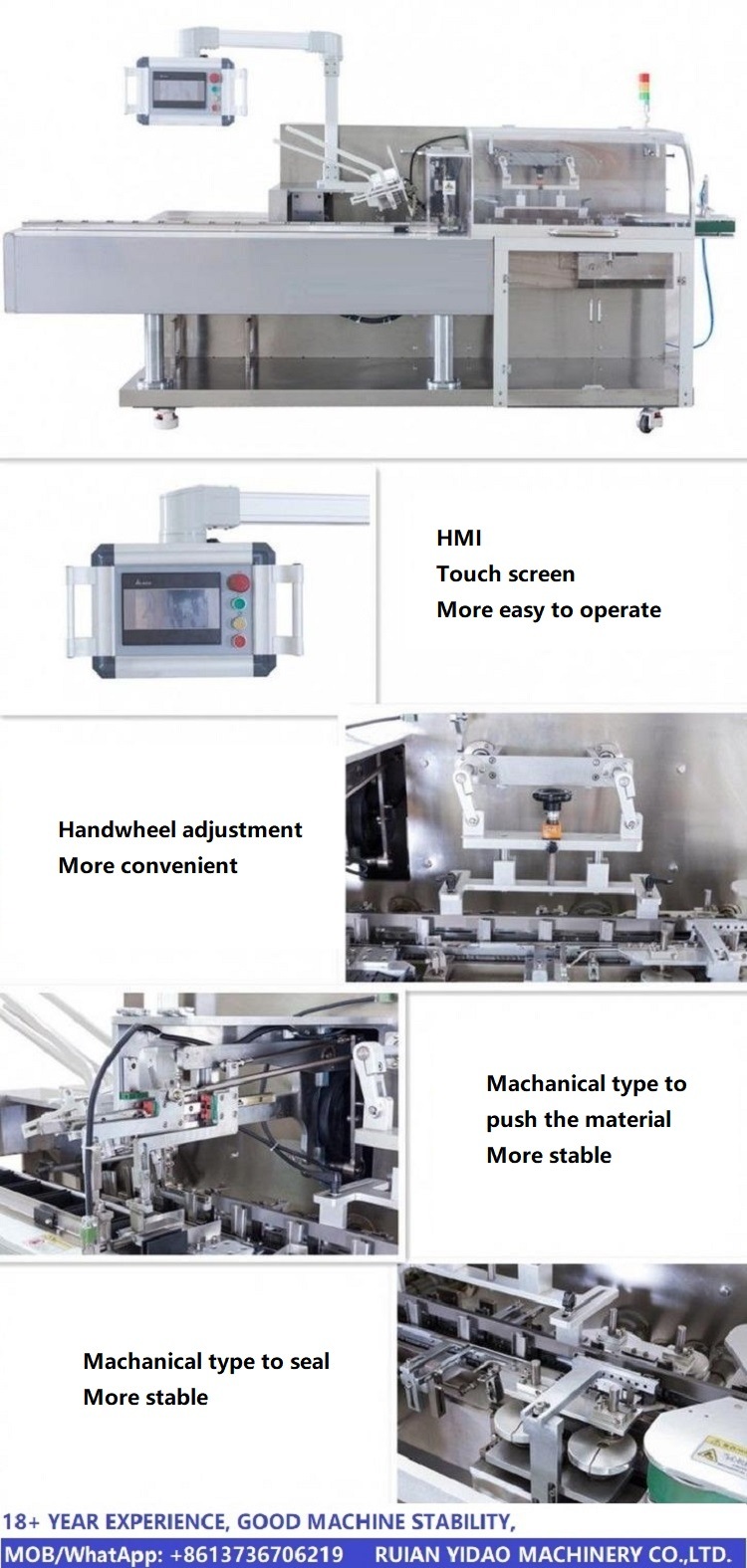

Main performance and structural characteristics:

1. It adopts automatic feeding, unpacking, feeding, sealing and output. And other packaging forms, the structure is compact and reasonable, and the operation and adjustment are simple;

2. Servo / stepping motor, touch screen and PLC programmable control system are adopted to make the display operation of the man-machine interface clearer and more convenient, with high degree of automation and more humane;

3. The photoelectric eye automatic detection and tracking system is adopted, and there is no product without suction box, which saves the packaging materials to the maximum;

4. Large range of packaging, easy adjustment, fast conversion between various specifications and sizes;

5. It is not necessary to change the mold to change the specifications, only adjustment is needed;

6. When there is no product or the product is not in place, the machine will idle without pushing the product. When the product is restored to supply, it will automatically run. When the product is in the box, it will automatically stop and the main drive motor overload protection device.

7. Automatic display of packing speed and counting:

8. According to customer requirements, a flip-up safety cover is adopted for easy operation and beautiful appearance.

9, can be linked with aluminum-plastic packaging machine, pillow packaging machine, three-dimensional packaging machine, bottling line, filling machine, labeling machine, inkjet printer, online weighing instrument, other production lines and other equipment to achieve linked production;

10. Can design various automatic feeders and cartoning systems according to the requirements of packaging materials;

11. According to customer requirements, the hot melt adhesive machine can be equipped with hot melt adhesive spray glue sealing box.

Technical parameter:

| Item | Parameter | Note | |

| Material type | |||

| Cartoning speed | 30-100 Box/minute | ||

| Paper box requirement | Paper quality | 250-400g/m2 | Requires flat surface and can be absorbed |

| Size range | L(50-250) x W(25X150) x K(15-70) | (LxWxH) | |

| Compressed air | Pressure | ≥0.6MPa | |

| Air consumption | 20m3/h | ||

| Power | 220V-380V 50Hz | ||

| Main motor | 1.5kw | ||

| Overall dimension LXWXH | 3500X1500X1800mm | Machine dimension | |

| Net weight | 1300kg | ||

Machine details:

Samples:

Factory tour:

RFQ:

Product detail pictures:

Related Product Guide:

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for OEM Manufacturer Pill Making Machine - Box Packing Machine for Biscuit – Yidao , The product will supply to all over the world, such as: Indonesia, Eindhoven, Argentina, With the support of our highly experienced professionals, we manufacture and supply best quality products. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the need of customers to meet the requirement of customers.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.