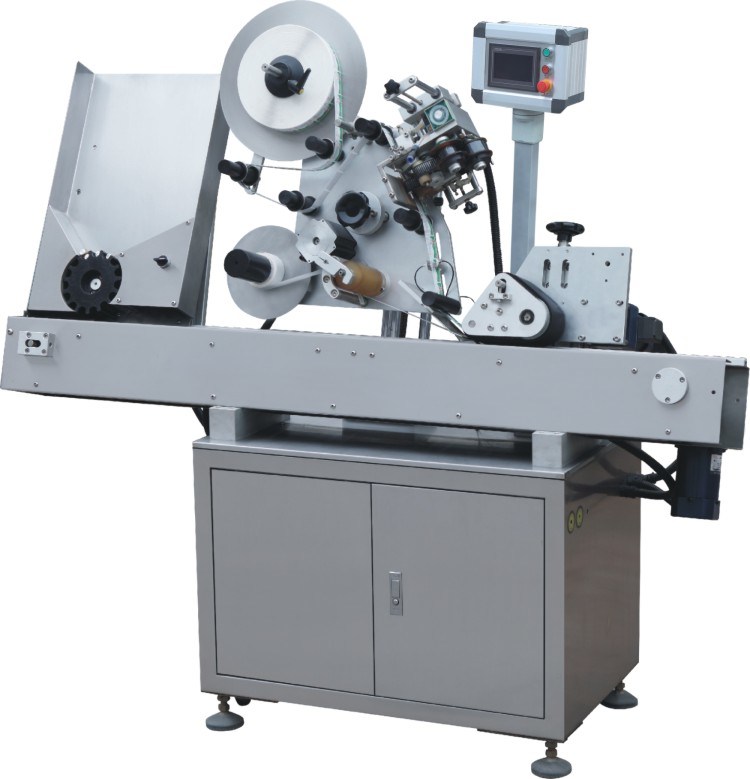

OEM/ODM Factory Food filling sealing machine - Shl-1582 Horizontal Labeling Machine – Yidao

OEM/ODM Factory Food filling sealing machine - Shl-1582 Horizontal Labeling Machine – Yidao Detail:

2.Equipment Features

1. Ultra wear-resistant label rolling mechanism, exclusive use of polyurethane material, durable and wear-resistant.

2. Advanced plum wheel feeding mechanism, simple, stable, reliable and non-fragile.

3. Imported bearings are used to install the conveying rollers to make the objects sensitive to roll to ensure the labeling quality.

4. Stable and durable machine base and various parts are all adopting standardized modular design, which is fully interchangeable and can be operated 24 hours to ensure safety and stability.

5. The chassis is made of stainless steel SUS304 material and T6 aluminum alloy, and will never rust, which meets the requirements of GMP pharmaceutical factories.

6. Powered synchronous tension control supply label, stable and fast supply, ensuring the speed and accuracy of label feeding.

7. Wheel-attached rolling bottle body makes label attachment more firm.

8. Synchronous positioning mechanism for labels, plus or minus 0.5mm.

9. Multi-point emergency stop button, an emergency stop button can be installed at an appropriate position on the production line to make the connection operation safe and production smooth.

10. Scope of application: Slim bottle-shaped labeling is available.

3.Parameter

| Model | SHL-1520 |

| Voltage | AC220v 50/60Hz |

| Power | 0.8KW/h |

| Output (pieces / minute) | 0-220 Pieces / minute (related to product and label size) |

| Operating direction | Left in right out or right in left out (can be connected to the production line) |

| Labeling accuracy | ±0 .5mm |

| Label type | Adhesive |

| Labeling object size | OD:10-30mm,H:35-90mm(Can be customized according to specific requirements) |

| Label size | Height15-90mm,Long 23-30mm |

| ID of label | 76 mm |

| OD of Label | 360 mm(max) |

| Weight (kg) | 300kg |

| Machine size | 1600(L)550 (W) 1550 (H) mm |

| Remark | Accept non-standard customization |

| Sr. | Product name | Supplier | Model | Qty | Remark |

| 1 | Stepper motor | Huanda | 86BYG250H156 | 1 | |

| 2 | driver | Huanda | 86BYG860 | 1 | |

| 3 | transformer | Chtai | JBK3-100VA | 1 | |

| 4 | Bottle inspection sensor | South Korea Autonics | BF3RX | 1 | |

| 5 | Check label sensor | South Korea Autonics | BF3RX | 1 | |

| 6 | Conveying motor | TLM | YN100-180W | 1 | |

| 7 | Bottle splitting motor | TLM | YN90-90W | 1 | |

| 8 | Power supply | Waiwan WM | S-75-24 | 1 | |

| 9 | Stainless steel | 304 | |||

| 10 | Aluminum | L2 | |||

| 12 | Touch screen | MCGS | CGMS/7062 | 1 | |

| 13 | PLC | Siemens | SMART/ST30 | 1 | |

| 14 | Coding machine | Shanghai | HD-300 | 1 | Option |

6. Application

7. RFQ

Product detail pictures:

Related Product Guide:

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for OEM/ODM Factory Food filling sealing machine - Shl-1582 Horizontal Labeling Machine – Yidao , The product will supply to all over the world, such as: Seychelles, Iran, Washington, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!