SR-120 Automatic Desiccant Inserter

Video 1, https://youtu.be/TQe7D3zWmxw

Automatic Bottle Unscrambler – > Automatic capsule tablet counting & filling machine -> Automatic Capping machine -> Automatic sealing machine -> Automatic labeling machine -> Automatic storage machine

https://youtu.be/GcIp_LJhGSA

Semi automatic bottle Unscrambler – > Automatic capsule tablet counting & filling machine -> Automatic Capping machine -> Automatic sealing machine

SR-120 Automatic Desiccant Inserter

SR-120 can automatically put the desiccant into the bottles, the bag feeding mechanism is driven by a stepper motor, so it is pulled out from the bag tray rack, and it is detected by the color mark sensor that control the length of bag, finally cut into the bottle. With the characteristic of sensitivity detection, accurate cutting, stable feeding and no jam. This machine is most important for the bottle filling line.

1.Intelligent connection, strong compatibility. It can be randomly and intelligently connected with customers’ front and rear production equipment, without the need for professional care, greatly saving labor costs.

2.It is suitable for various specification and shape of plastic bottles, such as round bottle, square bottle, flat square bottle and other special shape of bottles.

3.Strong versatility. Both colored and non-colored disc-shaped desiccant bags can accurately drop bottles.

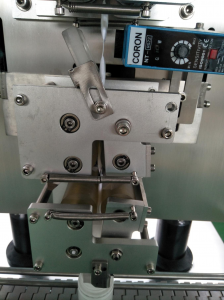

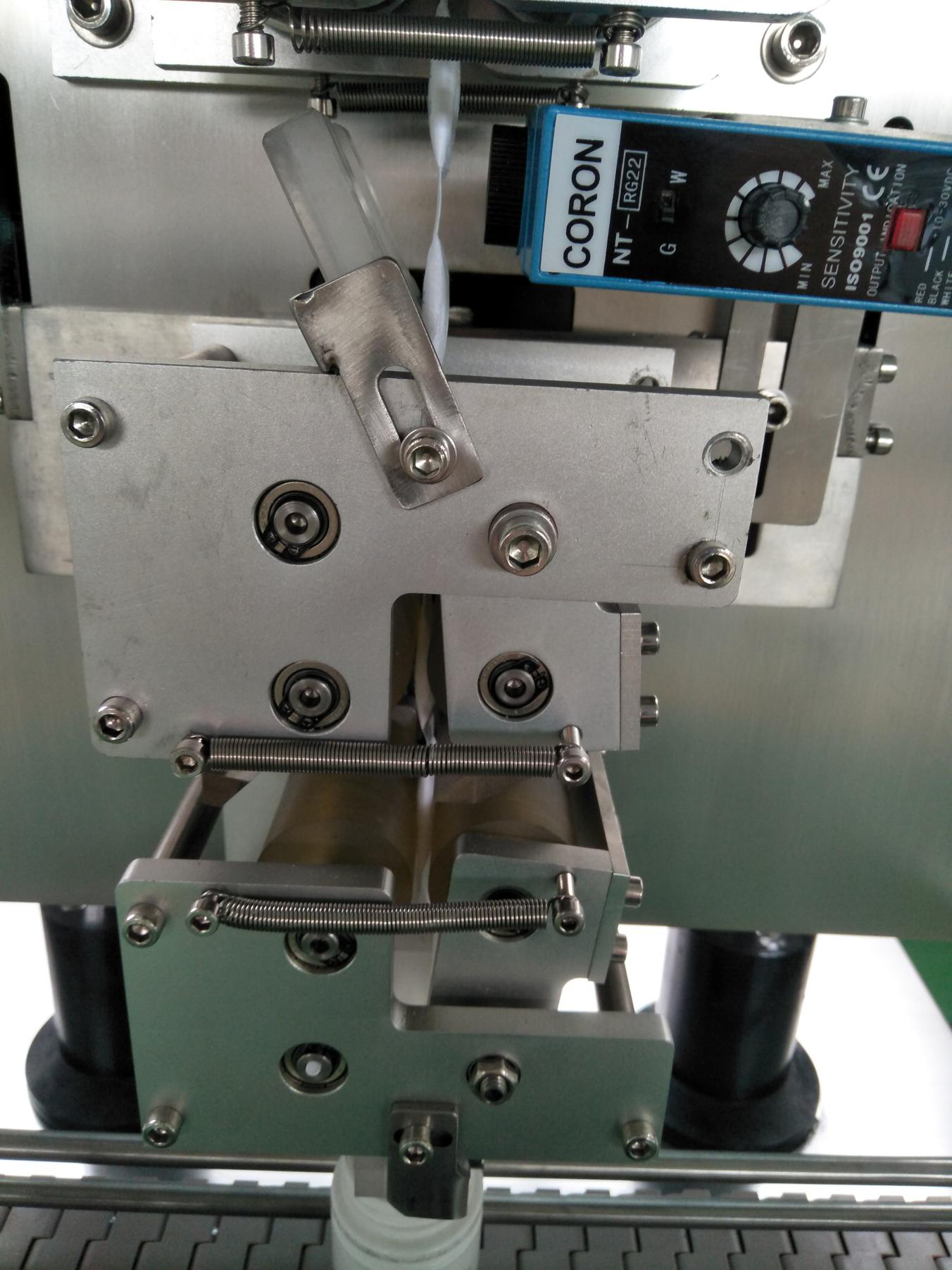

4.The gap between the two rollers that holding the desiccant bag can be automatically adjusted according to the thickness of the desiccant bag, avoid bag breakage during transporting.

5.Pre-put desiccant tape design is used to avoid uneven transmission of bags and ensure the accuracy control of bag length.

6.Self-diagnose errors and stop working to make alarm at errors as well as before driers going out, keep the working process continuous and inerrant.

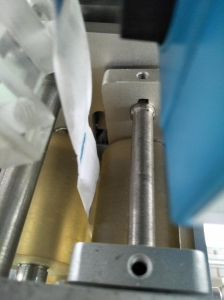

7.Cutting knife controlled by cylinder, with good accuracy and durable to avoid breakage of the desiccants.

8.The main electric component adapt Siemems brand, higher control precision and longer service life.

9.Panasonic detection photoelectric eye which has advantage of high dust resistance and higher detection accuracy.

10.It adopts a fully enclosed design and meets GMP requirements.

| Model | SR-120 |

| Production Capacity(bottles/min) | 20~120 |

|

Applicable Desiccant |

10-30 mm( W ) 20-50 mm( L ) |

| Size of Bottle | 15-500ml |

| Air Compressor | 0.6 Mpa |

| Total Power | 0.5kw |

| Power Supply | 220/380V 50/60 HZ |

| Outline Dim.(L×W×H)mm | 1000×700×1900mm |

| Weight | 350kg |

| Item | Manufacturer |

| Photoelectric eye for inducing bottle | Japan Panasonic |

| Motor | TQG |

| Main control board | Siemens |

| Touch screen | Siemens |

| Leakage Protection | Schneider |

| Switch button | Schneider |