Super Purchasing for Premade bag filling packing machine - Automatic Pet Food Chips Date Rice Peanut Grain Packaging Premade Bag Packing Machine – Yidao

Super Purchasing for Premade bag filling packing machine - Automatic Pet Food Chips Date Rice Peanut Grain Packaging Premade Bag Packing Machine – Yidao Detail:

Overview

OverviewBag given packaging machine replaces of manual packing type, which helps large enterprises, small and medium-sized enterprises reach to packaging automation, equipment mechanical grip will automatically take bag, print date, open the bag, to the metering device signal measurement and blanking, sealing, output. Main optional configuration for measuring material filling machine working platform, weight, scale, material hoist, vibrating feeder, finished goods transport hoisting machine, metal detection machine, etc.

It adopts Japan’s latest technology, under the total control system of PLC + POD, adopt mechanical structure, operation gradually replaced the operation of the pneumatic structure, to form a greater demands of the processing technology, easy operation, stable operation, maintenance, easy to clean, beautiful appearance.Performance and feature of machine

A. Rapid change of the specifications of the bag, bag width can be automatically adjusted by one button.

B. Single shaft and the CAM design: packing speed faster; more stable operation ; maintenance easier and reduce defective rate.

C. Modular heating, temperature control more accurate, heating fault have alarm prompt.

D. Advanced design idea, reduce the material loss, ensure the stability of equipment operation, extend the operating life of the equipment.

E. Simple and convenient operation, adopts the advanced PLC + POD (touch screen) electric control system and man-machine interface.

F. Machine have wide packaging range , it can packaging : liquid, paste, granule, powder, solid various bagging materials only. According to the different material with different metering device.

G. Machine use preformed bags & packaging design is perfect & good sealing quality to improve the quality and grade of the product.

Parameter of machine

| Model | ZP8-200/ZP8-260/ZP8-320 |

| Packing material | 3-side, four edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc |

| size | W:50-200/100-250/180-300 |

| Filling range | 10-1000g/20-2000g/30-2500g |

| Packing speed | 10-60bag/min(speed is determined by the product filling quantity) |

| Average precision | ≤ ±1 |

| Total power | 2.5KW |

| Dimensions | 1900mm X 1570mm X 1700mm/2000mm X 1570mm X 1700mm/2100mm X 1630mm X 1700mm |

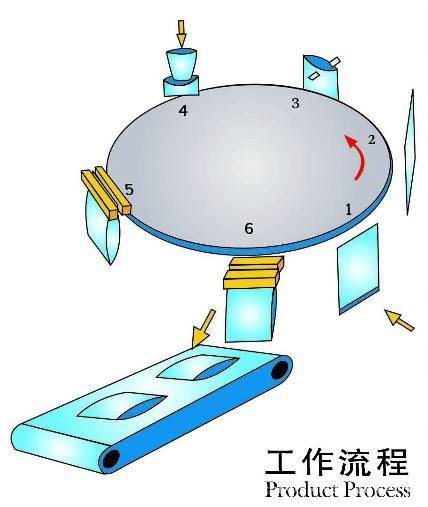

| Work flow | giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product |

| Applicable scope | 1. Block material: bean curd cake, fish, eggs, candy, red jujube, cereal, chocolate, biscuit, peanut, etc |

| 2.Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer | |

| 3.Powder type: milk powder, glucose, monosodium glutamate, seasoning, washing powder, chemical materials, fine white sugar, pesticide, fertilizer, etc | |

| 4.Liquid/paste type: detergent, rice wine, soy sauce, rice vinegar, fruit juice, beverage, tomato sauce, peanut butter, jam, chili sauce, bean paste | |

| 5.Class of pickles, pickled cabbage, kimchi, pickled cabbage, radish, etc | |

| 6.Other bagging materials | |

| Main standard parts | 1. Code printer 2. PLC control system 3.Bag opening device 4. Vibration device 5.Cylinder 6. Electromagnetic valve 7. Temperature controller 8.Vacuum pump 9. Inverter 10. Output system |

Machine of models

1,ZP8-200: Apply the bag width :50-200mm

2,ZP8-260:Apply the bag width :100-250mm

3.ZP8-320:Apply the bag width :180-300mm

Working flow

Samples

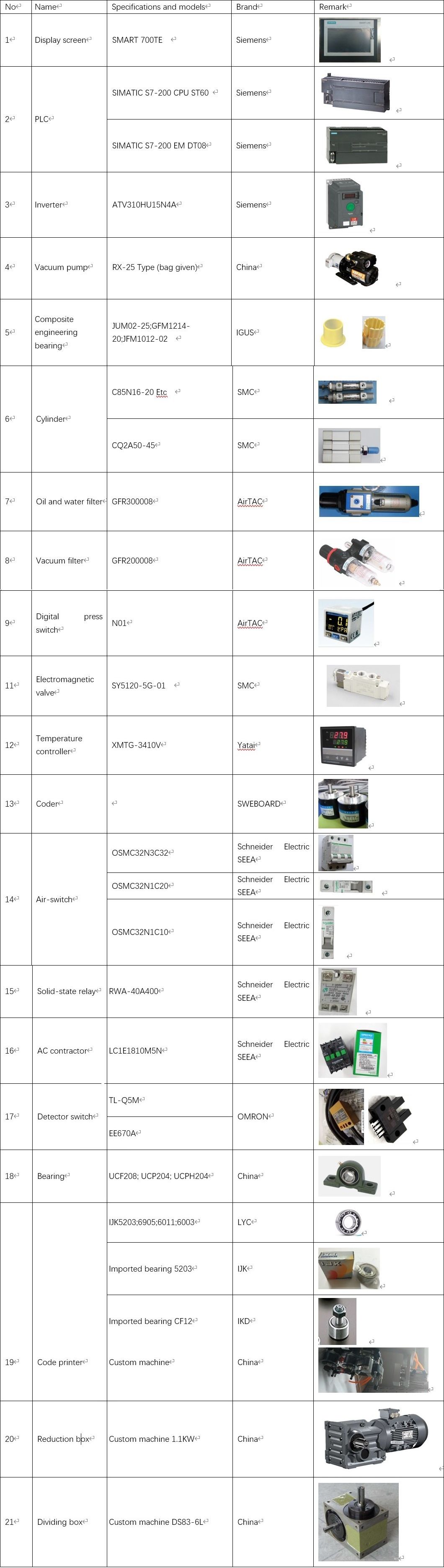

Configuration list

Additional location function

According to the bag specifications and form, combined with the production material, corresponding to choose the following additional features used in the machine:

1. 5 stations tong material (cylinder tong material, suitable for use of liquidity is not high and twice raw material adding)

2. 6 stations tong (cantilever barrels of material)

3. The exhaust (applicable to eliminate gas needed materials)

4. Under vibration (also called bag vibrate, applicable to material block or large material)

5. Level bags (applicable to zipper bags and soft bag)

6. Open the zipper bag (applicable to zipper bag)

7. Close zipper (applicable to zipper bag)

8. The open bag (applicable to zipper bag and not easy to open the bag)

9. Hopper vibration (applicable to low liquidity material)

10. Sweep dust and dust (applicable to powder)

Associated equipment

1. The elevator:

Z hoist, baffle hoist, hoist of large dip Angle, single bucket elevator, screw hoist, bowl type hoist, etc

2. The dose and filling machine:

Combination called contraction, cup, screw, filling machine, pickles, counting number machine, etc

3. The work platform

4. The finished product conveyor

Associated adopts (normal)

2. powder: host + screw hoist + screw said

3. grain: host + screw hoist + screw said (tiny particles)

Host + + platform + combination hoist said (large particle)

4. sour pickled cabbage: host + hoist + + pickles machine filling machine (liquid are used, can choose)

Host + + platform + combination according to hoist + filling machine (liquid are used, can choose)

5. pickle: host + pickles machine + promotion + filling machine, filling machine (liquid are used, can choose)

Host cup + + contraction hoisting machine, filling machine and filling machine (liquid are used, can choose)

6. pickles: host + + + platform + electronic scale hoist filling machine

Host + bowl type hoisting machine, filling machine (semi-automatic, artificial feeding)

(this form a complete set for the two kinds of material mixing, two feeding, example: Qing Shui Sun si, pickled peppers lotus root zone, etc.)

7. liquid, paste, host + filling machine

8. bag of bag: host + damper winding machine

Factory photos

Product detail pictures:

Related Product Guide:

Based on domestic market and expand abroad business is our enhancement strategy for Super Purchasing for Premade bag filling packing machine - Automatic Pet Food Chips Date Rice Peanut Grain Packaging Premade Bag Packing Machine – Yidao , The product will supply to all over the world, such as: Israel, Norway, Turkmenistan, By continuous innovation, we will provide you with more valuable products and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.