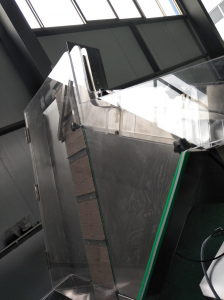

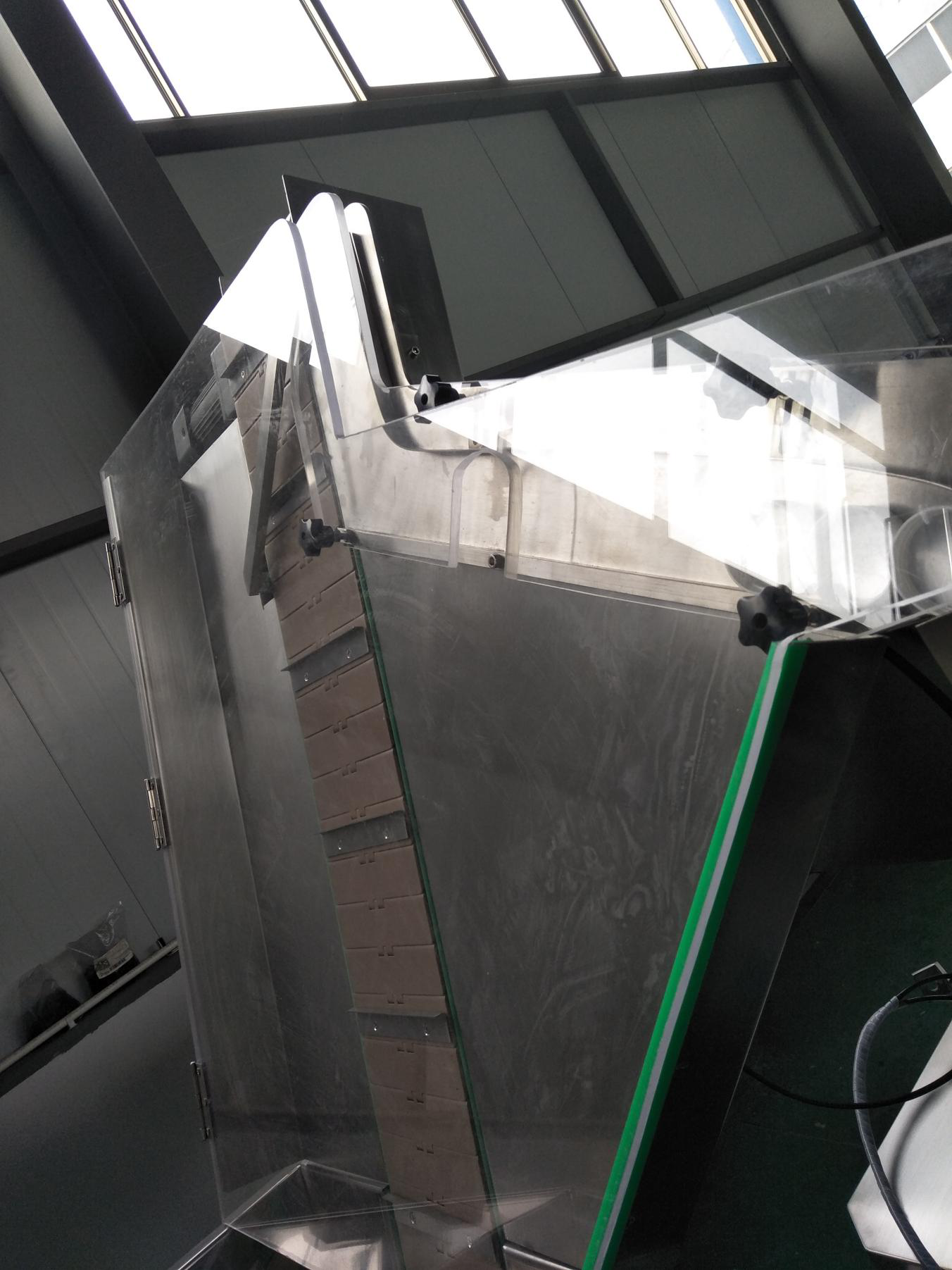

XG-120 High Speed Capping Machine

Video 1, https://youtu.be/TQe7D3zWmxw

Automatic Bottle Unscrambler – > Automatic capsule tablet counting & filling machine -> Automatic Capping machine -> Automatic sealing machine -> Automatic labeling machine -> Automatic storage machine

https://youtu.be/GcIp_LJhGSA

Semi automatic bottle Unscrambler – > Automatic capsule tablet counting & filling machine -> Automatic Capping machine -> Automatic sealing machine

XG-120 High Speed Capping Machine

This machine is widely used in foodstuff, pharmaceutical, daily product for capping various specification of product. With the function such as cap unscramble, reverse cap air rejection, cap in position detection, bottle in position detection, bottle splitting control, pre-pressed cap and rubber twisting cap etc. It is the ideal machine to be installed in the counting and bottling line, meets GMP requirements.

1.With dual functions of capping and twisting, it is more effective for some bottles that are difficult to cap.

2.Intelligent connection, strong compatibility. It can be randomly and intelligently connected with customers’ front and rear production equipment, without the need for professional care, greatly saving labor costs.

3.It is suitable for various specification and shape of plastic bottles, such as round bottle, square bottle, flat square bottle and other special shape of bottles.

4.The tightness of capping and twisting mechanism can be adjusted, 100% ensure the bottle, cap won’t be damaged and no scratched.

5.It is easy to change different size of bottle and cap, only need 10 minutes to replace the spare parts.

6.Swing type twisting rubber wheel, it can control the twist force accurately, which greatly reduce the wear of rubber wheel.

7.Self-diagnose errors and stop working to make alarm at errors and missing bottles, caps. It is also have the rejection system without aluminum foil after capping.

8.Equipped with lifting motor, which can realize the main machine automatically lifting.

9.The contacted parts with bottle and cap adopt non-toxic belt and non-toxic capping wheel.

10.The main electric component adapt Siemens brand, higher control precision and longer service life.

11.Panasonic detection photoelectric eye which has advantage of high dust resistance and higher detection accuracy.

12.The machine shell are made of SS304, meeting the GMP requirements.

| Model | XG-120 |

| Production Capacity(bottles/min) | 20~120 |

| Specification of bottle | ¢30≤Diameter≤¢80mm |

| Specification of cap | ¢25≤Dia. of cap≤¢60mm |

| Height of Bottle | ≤150mm |

| Air Compressor | 0.6 Mpa |

| Total Power | 1.8kw |

| Power Supply | 220/380V 50/60 HZ |

| Outline Dim.(L×W×H)mm | 2200×1100×1850mm |

| Weight | 600kg |

| Item | Manufacturer |

| Photoelectric eye for inducing bottle | Japan Panasonic |

| Motor | TQG |

| Main control board | Siemens |

| Touch screen | Siemens |

| Converter | Delta |

| Leakage Protection | Schneider |

| Switch button | Schneider |